timers

Timer

Kitchen timer

Some timers sound an audible indication that the time interval has expired.

Time switches, timing mechanisms which activate a switch, are sometimes also called "timers".

Contents

Hardware timers

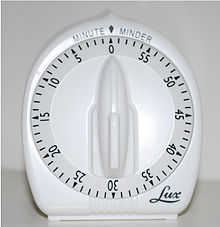

Mechanical timers

A typical mechanical timer

The simplest and oldest type of mechanical timer is the hourglass, in which a fixed amount of sand drains through a narrow opening from one chamber to another to measure a time interval.

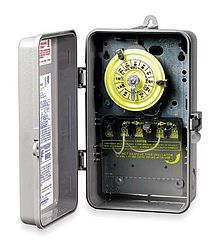

Electromechanical timers

An electromechanical timer

An electromechanical cam timer uses a small synchronous AC motor turning a cam against a comb of switch contacts. The AC motor is turned at an accurate rate by the alternating current, which power companies carefully regulate. Gears drive a shaft at the desired rate, and turn the cam. The most common application of this timer now is in washers, driers and dishwashers. This type of timer often has a friction clutch between the gear train and the cam, so that the cam can be turned to reset the time.

Electromechanical timers survive in these applications because mechanical switch contacts may still be less expensive than the semiconductor devices needed to control powerful lights, motors and heaters.

In the past, these electromechanical timers were often combined with electrical relays to create electro-mechanical controllers. Electromechanical timers reached a high state of development in the 1950s and 1960s because of their extensive use in aerospace and weapons systems. Programmable electromechanical timers controlled launch sequence events in early rockets and ballistic missiles. As digital electronics has progressed and dropped in price, electronic timers have become more advantageous.

Electronic timers

A simple digital timer. The internal components—including the circuit board with control chip and LED display a battery, and a buzzer—are visible.

Many timers are now implemented in software. Modern controllers use a programmable logic controller rather than a box full of electromechanical parts. The logic is usually designed as if it were relays, using a special computer language called ladder logic. In PLCs, timers are usually simulated by the software built into the controller. Each timer is just an entry in a table maintained by the software.

Digital timers are used in safety devices such as a gas timer.[further explanation needed]

Software timers

These types of timers are not devices nor parts of devices; they exist only in lines of code. They rely on the accuracy of a clock oscillator usually built into a hardware device that runs the software.Software applications

Nowadays when people are using more and more mobile phones, there are also timer apps that mimic the old mechanical timer, but which have also highly sophisticated functions. These apps are also easier to use daily, because they are available at once, without any need to purchase or carry the separate devices, as today timer is just a software application on a phone or tablet. Some of these apps are countdown timers, stopwatch timers, etc. These timer apps can be used for tracking working or training time, motivating children to do tasks, replacing an hour glass in board games, or for the traditional purpose for tracking time when cooking and baking.Apps may be superior to hour glasses, or to mechanical timers. Hour glasses are not precise and clear, and they can jam. Mechanical timers lack the customization that applications support, such as sound volume adjustments for individual needs. Most applications will also offer selectable alarm sounds.

Some timer applications can help children to understand the concept of time, help them to finish tasks in time, and help them to get motivated.[3] These applications are especially used with children with special needs like ADHD,[4] Down Syndrome, etc., but everybody else can also benefit from them.

Other types

Computer systems usually have at least one hardware timer. These are typically digital counters that either increment or decrement at a fixed frequency, which is often configurable, and which interrupt the processor when reaching zero. An alternative design uses a counter with a sufficiently large word size that it will not reach its overflow limit before the end of life of the system.More-sophisticated timers may have comparison logic to compare the timer value against a specific value, set by software, that triggers some action when the timer value matches the preset value. This might be used, for example, to measure events or generate pulse width modulated waveforms to control the speed of motors (using a class D digital electronic amplifier).

One specialist use of hardware timers in computer systems is as watchdog timers, that are designed to perform a hardware reset of the system if the software fails.

Comments

Post a Comment